MyCell

︎ Creator:

Noah Chalfant

︎ Supervisors: Jennifer Bissonnette & Peter Yeadon

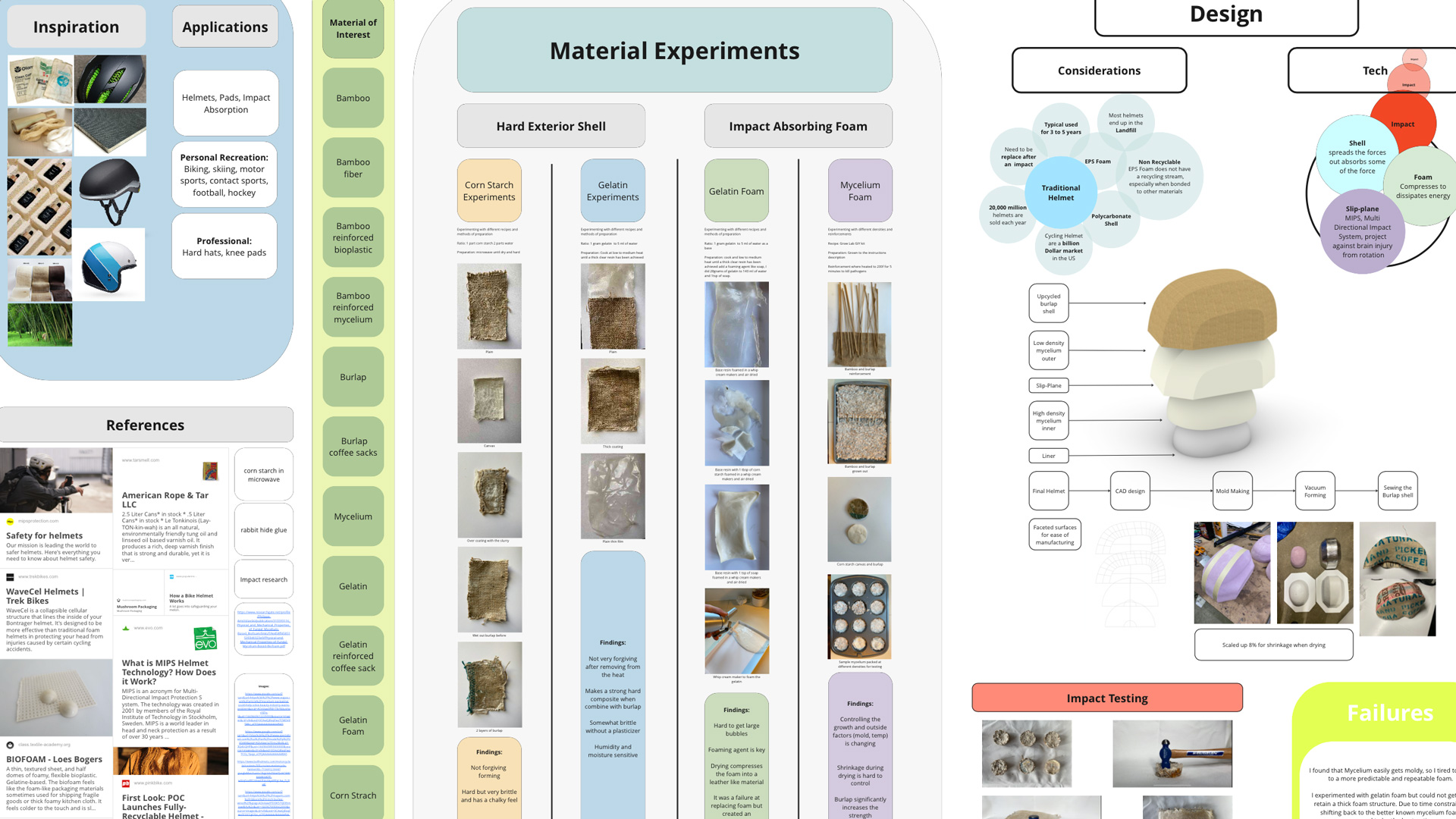

Because contemporary helmets are made up of many different types of polymers that are bonded together into a forever product destined for the landfill, this biomaterial study by Noah Chalfant was driven by the need for impact-protection headwear that’s more sustainable. After Noah explored the properties of mycelium (impact absorbing, lightweight, compostable), it seemed like the perfect material to replace conventional polymers used in helmets.

Upon further research, Noah found that using mycelium presented three main challenges: day-to-day durability, weather resistance, and performance. To solve these problems, he looked into other biomaterials and composites. Settling on upcycled burlap coffee sacks as an outer shell reinforcement, he experimented with different bio-resins made of kelp, corn starch, and gelatin to produce a biocomposite. Testing led him to choose a gelatin-based resin for the composite, as it was the strongest and offered a readily repeatable method. When finished with a linseed oil or a wax, the burlap/gelatin biocomposite forms a weather resistant exterior shell.

For performance, Noah looked at the latest helmet tech trends, which use slip-planes or a Multi-directional Impact Protection System to allow the helmet to rotate a few centimeters in any direction during impact, thus minimizing the chances of a brain injury. He was able to control the growth of the mycelium to achieve similar functionality in his helmet, by creating two molds for growing two mycelium forms separately – an inner form and an outer form – and then placing one grown form within the other and allowing them to grow together, creating a weak zone of pure mycelium that will shear during impact.

︎ Supervisors: Jennifer Bissonnette & Peter Yeadon

Because contemporary helmets are made up of many different types of polymers that are bonded together into a forever product destined for the landfill, this biomaterial study by Noah Chalfant was driven by the need for impact-protection headwear that’s more sustainable. After Noah explored the properties of mycelium (impact absorbing, lightweight, compostable), it seemed like the perfect material to replace conventional polymers used in helmets.

Upon further research, Noah found that using mycelium presented three main challenges: day-to-day durability, weather resistance, and performance. To solve these problems, he looked into other biomaterials and composites. Settling on upcycled burlap coffee sacks as an outer shell reinforcement, he experimented with different bio-resins made of kelp, corn starch, and gelatin to produce a biocomposite. Testing led him to choose a gelatin-based resin for the composite, as it was the strongest and offered a readily repeatable method. When finished with a linseed oil or a wax, the burlap/gelatin biocomposite forms a weather resistant exterior shell.

For performance, Noah looked at the latest helmet tech trends, which use slip-planes or a Multi-directional Impact Protection System to allow the helmet to rotate a few centimeters in any direction during impact, thus minimizing the chances of a brain injury. He was able to control the growth of the mycelium to achieve similar functionality in his helmet, by creating two molds for growing two mycelium forms separately – an inner form and an outer form – and then placing one grown form within the other and allowing them to grow together, creating a weak zone of pure mycelium that will shear during impact.